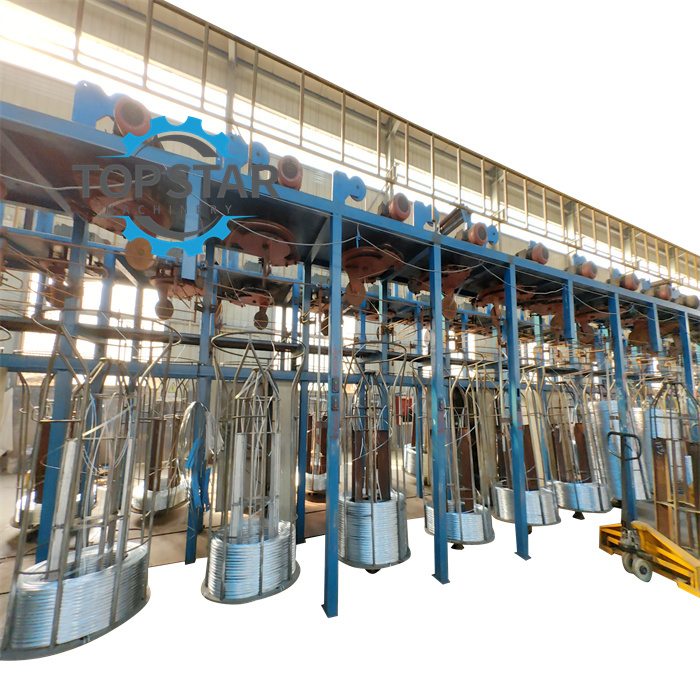

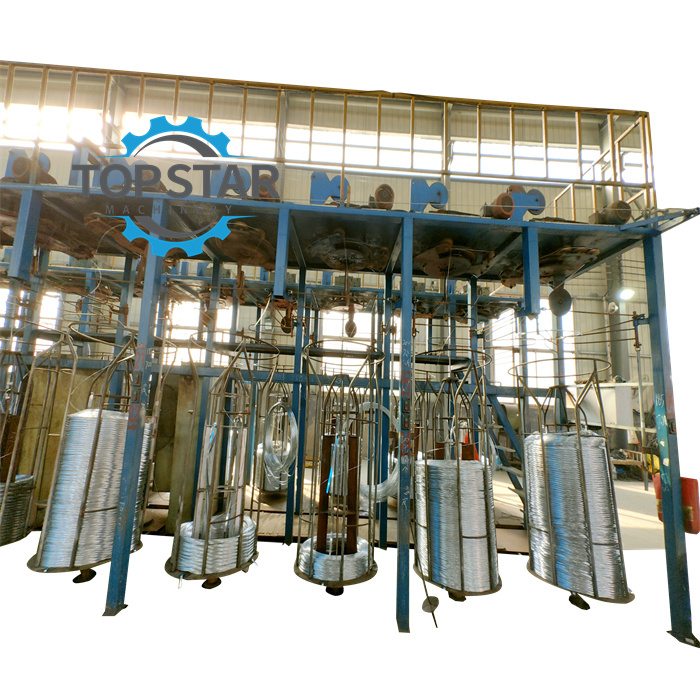

0.9-1.6mm hot dipped galvanized wire production line

Galvanized Wire diameter :0.9--1.6 mm

Zinc coating thickness: 30--60 g/m²

Number of galvanized wires: 40--70 line

Galvanized Wire spacing: 30 mm

Annealing method :On line annealing

Zinc layer control: Wipe system

Wire pay-off system: Wire spool

Wire take-up system: Elephant trunk or inverted coils type