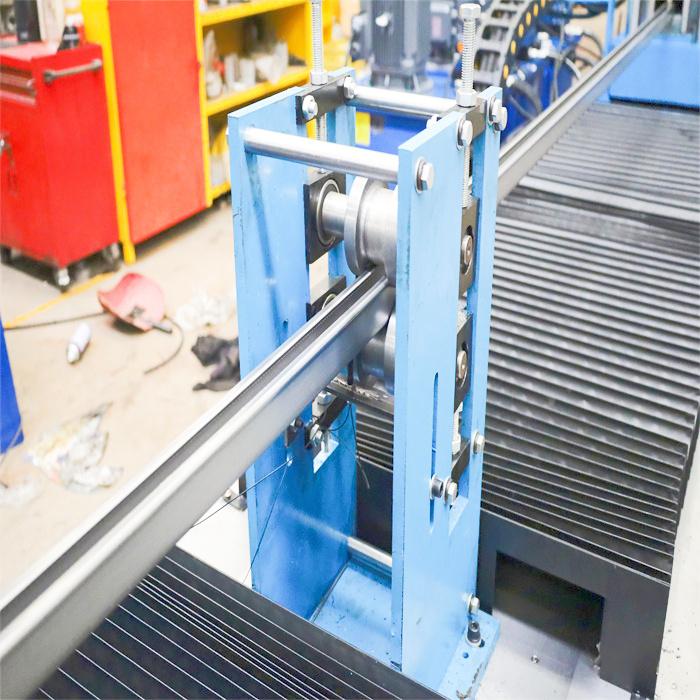

Strut Channel Roll Forming Machine U Bracket Solar Panel Mounting Structure Making Machine

1)strut channel Material:The production model is 41*41 41*21 21*21 41*62 41*82

2)strut channel thickness of 1.5-2.5 mm

3)steel strut channel hot dip galvanized steel slotted c channel unistrut c z u purlin

4)strut nut channle roll forming machine speed:12-25 m/min